I also did a pit of peg-painting, though, although not military related it did get me some practise. It was just a couple of peg-people gifts for some friends...

As I say, not military but these little figures did teach me a couple of things that I can bring forward and apply to my peg-soldiers.

One of the main lessons was about using 'permanent' markers. I tried using water-proof pens for drawing the fine outlines and to begin with it looked like it was working well (I invested in some good quality permanent markers this time). But, much to my horror, the spray varnish I used to gloss the finished figures reacted with the pen ink and the lines all ran!

After the initial shock, I picked myself up and did a careful repair job and managed to salvage this model. The lesson for me was - stick to outlining with acrylics and a brush!

I *believe* that the spray acrylic lacquer I use although 'acrylic' contains a spirit based propellant (?) and this is what reacted and reactivated the pen ink and made it run. I've bough a can of brush on varnish to experiment with to see if this makes any different, as using pens is a quick and effective way of drawing sharp lines. We shall see.

Anyway, back to military themes...

My plan is to do a small army of peg-soldiers for a tabletop game based on the Portable War-game rules. In the format I have chosen 'regiments' will be symbolic and made up of six figures in each unit (for infantry).

The campaign I am interested in is the Franco-Prussian War of 1870/71, ideal Victorian 'toy soldier' inspiration. This conflict featured a plethora of colourful uniforms on both sides, particularly because (and forgive me here because I am not a historian) because at this point Germany was still a sort of confederation of allied independent kingdoms.

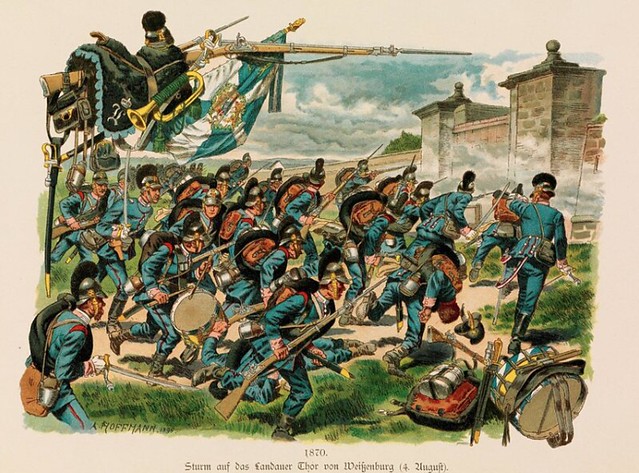

|

| Just one of the many varied uniforms of the German Allies, here Bavarian troops are involved in an assault at the battle of Wissembourg, 1870. |

I hope to illustrate this diversity in a - as yet - non-unified greater Germany by including some of the less well-known troop types and not just the infamous, Pickelhaube helmeted Prussians!

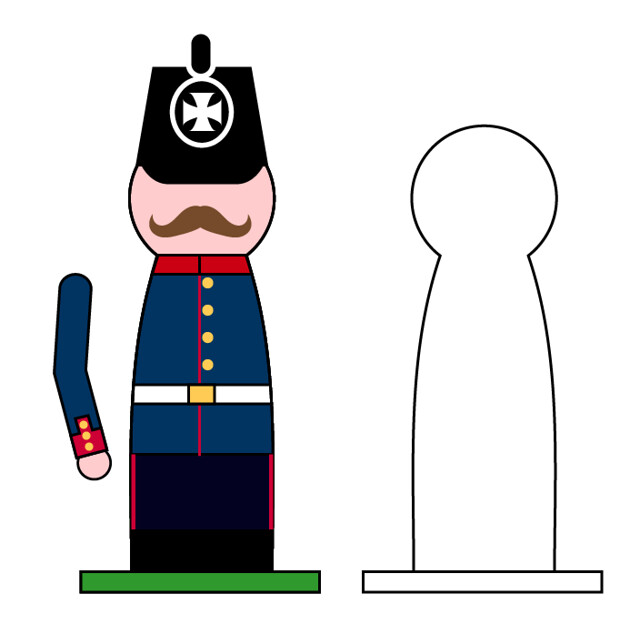

|

| My sketch for a German infantryman (Landwehr). I've simplified the uniform and equipment to compliment the peg format and also to be a little more 'toy soldier' looking. |

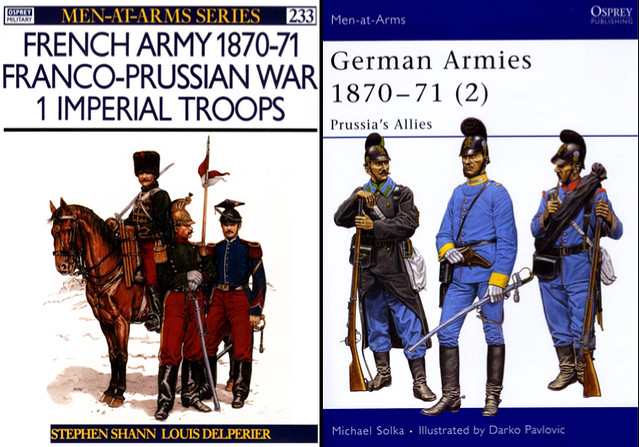

To help me along in my uniform choices I am referring to Osprey's excellent Men-at-Arms 'German Armies' 1870-71 (vols. 1 & 2) and their 'French Army 1870-71' (vols. 1 & 2).

Something I've mentioned before is my worries over how to replicate the distinctive headgear. Cutting all my 'parts' from just the basic wooden peg, while satisfying in it's way, is a bit limiting, especially if you want to create more complex components. (Think about the unique German Pickelhaube helmet and you'll understand the problem...How do I cut that out of a cylindrical piece of wood?)

|

| A Prussian Pickelhaube, how would I make that from a peg? |

So, after a long think I decided to 'cheat' and make the headgear as composite object using as much wood as I can but then adding the tricky details using modelling putty to make a master prototype. Once done, I will them copy the design by creating mould and casting a clone in Milliput putty...Simples. (?)

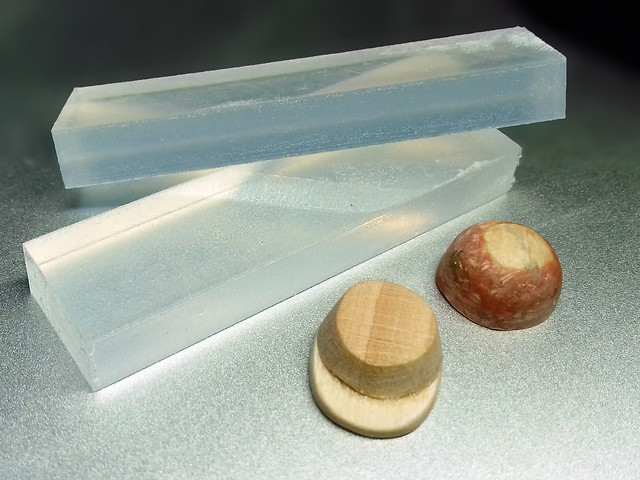

I'll be having a crack at this process using a product called 'Instant Mold' (I don't want to get into resin casting for these short run duplications.

So, to begin I need some basic wooden geometric or primary shapes to start off with. I'm starting with a French Kepi and the dome for a Prussian Pickelhaube. Although the Kepi is complete and made from wood it is a bit tricky to duplicate because of the sloped and obliquely cut top, which is why I want to cast it instead. The Pickelhaube dome will be the basis for further sculpting using Milliput putty, but I want a shaped blank to start with, so I'm casting this too...

This *should* be a easy process (according to the YouTube tutorials I have watched) and should simply entail my pressing the hat shapes into the softened Instant Mold to create copies of the shapes I want to cast. Going on my experience, though, nothing is ever straight forward the first time you do it!

First issue...How many sticks of Instant Mold do I use? I guess this is the sort of knowledge that will only come with experience...I'm going to guess two...

Good guess! Turns out you need to allow a good margin of Instant Mold to surround your object (remember you are *pressing* the object into the mould material) and you have to make sure you have enough depth of Instant Mould (so you don't press the object right through the Instant Mold).

Anyway, to the process...You can measure the temperature and boil your water in a pan (or nuke it in a microwave) but I simply boiled the kettle and that seemed to suffice. The Instant Mold was dropped into the water (in a Pyrex bowl) and began to soften in the boiling water after about two to three minutes...

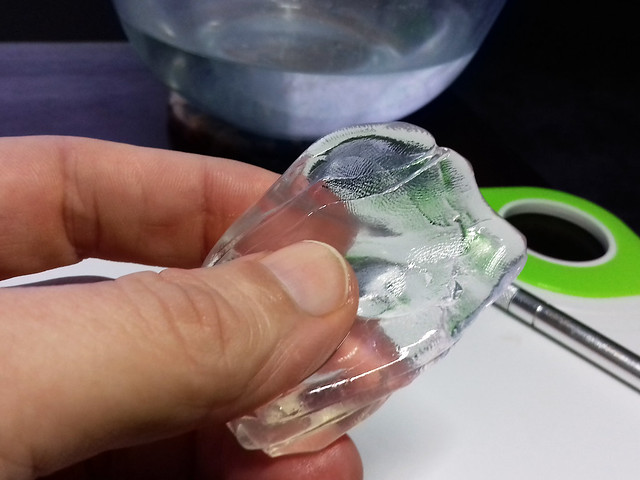

|

| Mind you fingers getting the Instant Mold out the boiling water. I used a craft knife to get it out. |

It took me two goes as I worked too slowly the first time and it started to harden as I was moulding the Instant Mold around my objects (you live and learn)...BUT, the great thing about Instant Mold is that if you are not happy with your mould, then just pop it back into more boiling water and start gain!

I tried to form the Instant Mold into a sort of block(ish) around the object and press it firmly against the object to ensure I get an exact clone of my original shape. Being clear helps to spot air pockets, gaps or bubble I guess. I then left the mould to cool and harden, I didn't really time this but it didn't take all that long.

One thing I tried out, though, was that I used a new craft knife blade and trimmed the hardened Instant Mold down, roughly level with the top of the Pickelhaube blank. I did this to see if I could do a neat casting exactly to the shape of my object, without too much excess that I will have to trim off later. The Kepi mould was left alone to see what would happen...

And so, finally, onto the casting stage. Again, this should be simple, I just need to press my chosen casting medium (Milliput in my case) into the mould - hopefully without air bubbles or gaps (here the transparency of Instant Mold helps gain) - and then leave the casting to dry. Milliput normally takes overnight to cure, but there are other mediums that dry a lot quicker (I'll try some of these later), but I like the final hardness of Milliput so I'm willing to wait...

Now, obviously, my mould is a very simple single-piece press mould, but Instant Mold is capable of being used to create a more advanced two-part mould. These might create a neater casting with a little less waste, but I think I might get a bit more economical in my casting with a bit of practise.

Anyway, the wait begins. So I'll end here and see how my castings work out. But it's good to get producing again.

Just a wee thought! Maybe you should use your scalpel to cut away the excess putty on the Kepi while it is still soft. Might be a bit tricky once it has hardened.

ReplyDelete