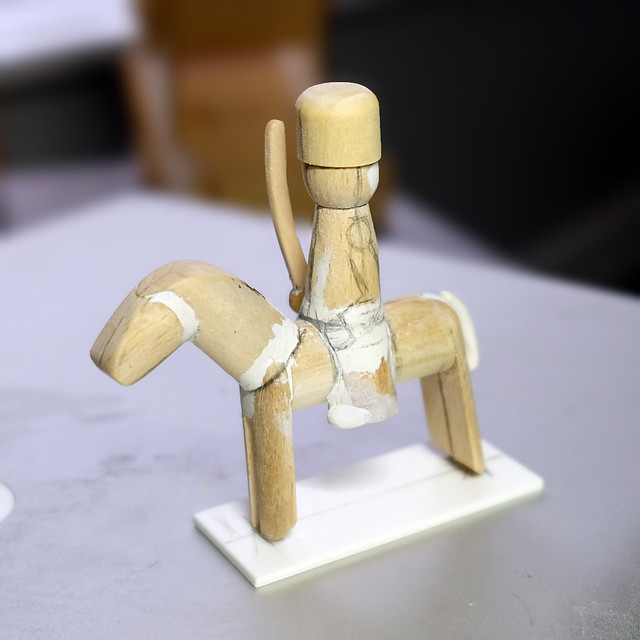

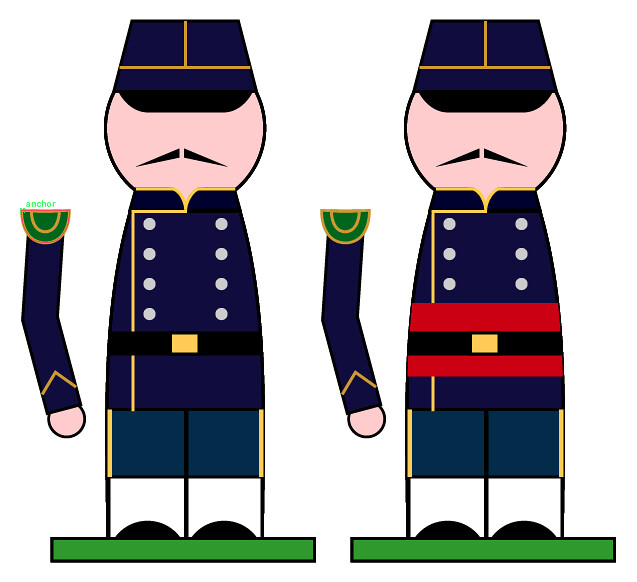

Having constructed my very first peg unit, it's time to get down to the nitty-gritty with some painting. As I mentioned in part 1 of this series I had taken the time to do a colour sketch of how I wanted my soldiers to look (having simplified the uniform design a little to suit the peg soldier format).

However, I think I have resolved the one issue I had with the uniform colour - based on the contradictory information provided by some of the historical illustrations I had gathered - and that was the colour of the Chasseurs trousers. I found an excellent website called

'Images De Soldat'...

The website of the author-illustrator

André Jouineau, it contains about 1500 colour plates which reference the uniforms of various nations from 18th century to World War 2. And I was delighted to find a wonderful plate with the uniforms of the

Chasseurs à pied from1870.

(You pay a nominal sum to download the full-sizes plates, but it's worth the €2 if you are serious about your modelling projects.)

While I can't show you the copyrighted illustrations I can confirm that the trousers were, indeed, in a lighter blue (somewhat akin to RAF uniform blue, but a shade darker). So my uniform sketch has now been amended...

The soldier on the right is wearing a rather flamboyant red

cummerbund (or cummerband). I'm in two minds whether to include this item in my peg models as - although it is very dashing - I cannot pin down what the actual meaning was of it's inclusion as part of the regiment's uniform. All I have found is this short mention in Wikipedia:

"The units of the French Army of Africa (such as the Zouaves or the Chasseurs d'Afrique) wore cummerbunds of 2 different colours: blue for European soldiers and red for Native recruits."

This does not seem to fit in with the pictorial reference I have from

Images De Soldat, as the example soldier was clearly of European origin, so the red sash clearly has some other meaning. They

may have been worn, perhaps, to indicate that the unit has seen colonial service (but this is a guess on my part).

[Edit: Nope, I cannot resolve this conundrum, so I will not include the sash - however pretty it is - as the majority of reference I have does not include it.]

Now, On with the Painting...

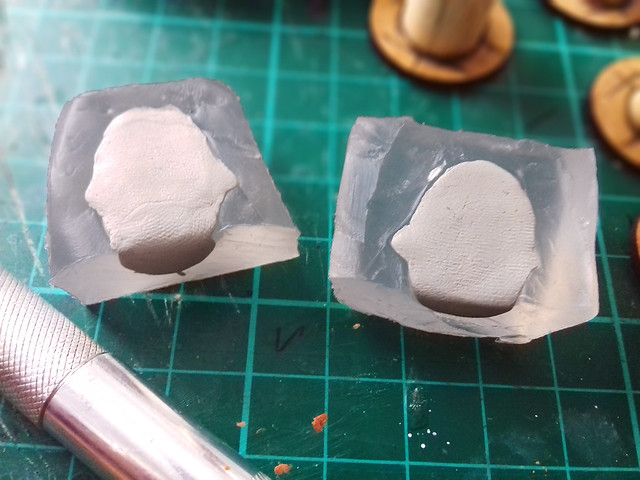

I'm sticking to my grey primer as it seems a really good base for bright colours (white can be a little bit of a pain to cover sometimes)...

Downside of doing these little fellas in grey is that - with the keeps - it makes me very tempted to do an ACW Confederates! :) (Maybe another time?)

Picking Paints & Colours

One thing I don't like to do so much is mix up special colours, I'd rather buy the exact colour match (or closest thing) in bottle form. It's not that I'm lazy, it's just that - from experience - I know that if I want to duplicate a mixed colour further down the line it's a pig to get an precise match. It's far easier to just know what number Vallejo or Humbrol to buy.

So here's my paint list for my French Chasseurs:

• Gold Piping:

- Vallejo Model Color [948] Golden Yellow

• Dark Blue (jacket & kepi):

- Black undercoat base with Vallejo Model Color [899] Dark Prussian Blue over the top.

• Airforce Blue (trousers):

- Citadel Kantor Blue.

• Flesh:

Vallejo Model Color [815] Basic Skintone.

• Wood:

-Vallejo Model Color [846] Mahogany Brown.

I decided to tackle this paint scheme by starting with the 'gold' piping, in the hope I could get some nice (fairly) even lines!

A Case of the Blues

I've been here before...Quite a while ago I had a go at painting a Black Hat 1/32 scale white metal 1890 French Infantryman. Getting the right deep dark blue caused me lots of grief, I just couldn't get the shade right. Eventually, I managed to achieve a colour I was happy with, but only by means of a complicated mix of various blues - something I don't want to go through again...

Depending on the lighting it's nearly black, but not quite...I think it's what's called 'midnight blue'.

This time I decided to go for a simpler approach and in an attempt to make the richness of the blue colour more intense, though still dark. What I decided to do was to lay down an undercoat of straight black, and then to paint a rich Prussian Blue over the top. The resultant effect was for the black undercoat to darken the subsequent blue coat BUT the blue retained it's richness.

Now, Slap it On...

Enough over-thinking about colours, let's get on with some hairy-stick action! I begin by filling in the spaces between my yellow piping on the hats (and will eventually work my way down to the jackets) with a black base coat...

I also laid down the flesh tones and the whites of the soldiers eyes. I've tried to vary the hair styles and the shape of the moustaches, hopefully these will be suitably French looking (to contrast with the more teutonic curled moustaches of the German opposition).

|

| At this point the jackets are just the black undercoat. |

And now the slow slog as I repeat the painting until the figures are complete! (Though, to keep me from getting a bit bored with the repetition - thank goodness I'm only doing a unit of 6 - I am already making a start on the first of my Prussian troops.)